- +31-624-845-535

- info@plabottles.eu

- in need of compostable packaging?

- Let's connect

LCA of PLA bottle solutions for extended shelf‑life (ESL) milk

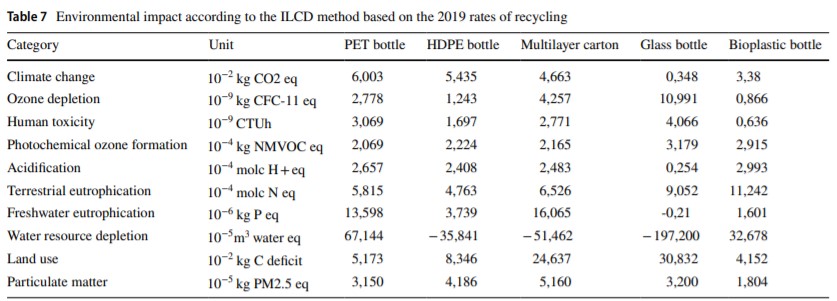

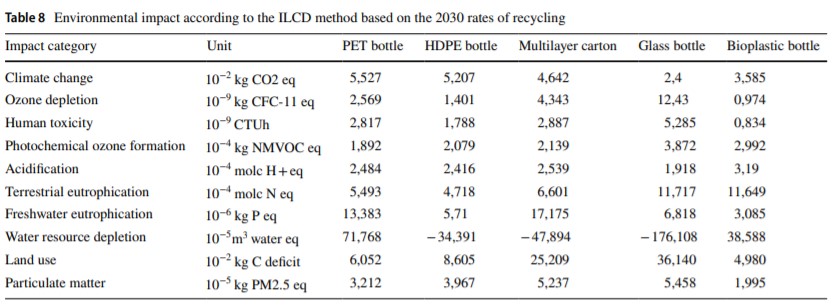

The dairy market is one of the most important sectors worldwide, and milk packaging contributes to over one-third of the global dairy packaging demand. The end of life of the PLA bottles is a critical stage of their life cycle, as demonstrated by the fact that disposable bottles are one of the litter items that are most found on beach shores. The aim of this paper is to analyse the performance of PLA bottles compared to other alternatives currently in use in the milk packaging sector, using the life cycle assessment (LCA) methodology. PLA bottles can be a powerful means to create a circular economy for disposable items. A PLA-based bottle is compared to a PET bottle, a HDPE bottle, a multilayer carton, and a glass bottle. In the analysis, also secondary and tertiary packaging is included. The functional unit chosen is “the packaging needed to contain 1 L of ESL milk and to guarantee a shelf life of 30 days”. Two sensitivity analyses are also performed in order to assess the infuence of the end-of-life stage on the total impact. The results show that, in accordance with the assumptions of an ideal scenario, bioplastic system has a better performance than fossil-based systems and multilayer carton in the categories of climate change, ozone depletion, human toxicity, freshwater eutrophication, particular matter, and land use. The recycling scenario strongly changes the impact of the glass packaging system in the considered categories.

Methodology and data

The present analysis of LCA of PLA bottle solutions for extended shelf‑life (ESL) milk is made following the life cycle assessment methodology. The software SimaPro 9 (PRé Consultants 2019) was used to perform the calculation. As prescribed by the ISO 14040 series (International Organization for Standardization 2006a; 2006b), the following phases are presented:

• Goal and scope defnition

• Life cycle inventory

• Life cycle assessment

• Life cycle interpretation

LCA of PLA bottle - Goal and scope definition

The aim of this analysis is to perform a life cycle assessment of diferent packaging systems used for extended shelf-life (ESL) milk. All the items are modelled through the main materials they are made of. In detail, the following packaging systems are considered.

The PET bottle system. The bottle is made of polyethylene terephthalate (PET), the cap is made of high-density polyethylene (HDPE), and the label is made of polyvinyl chloride (PVC).

• The HDPE bottle system. The bottle is made of high-density polyethylene (HDPE), the cap is made of polypropylene (PP), and the label is made of polyvinyl chloride (PVC).

• The multilayer carton system. Beyond the multilayer aseptic carton, a cap made of high-density polyethylene (HDPE) is included in this system. No label is included.

• The glass bottle system. The bottle is made of glass, the cap is made of steel, and the label is made of Low-density polyethylene (LDPE).

• The bio-plastic bottle system. The bottle is made of PLA, and the label and the cap are mainly made of polylactic acid (PLA) and poly butylene succinate (PBS). The items made of PLA and PBS are compostable. Biodegradability under composting conditions is determined by applying the standard EN 13,432 (CEN 2000). In all the systems, secondary and tertiary packaging is also included.