- +31-624-845-535

- info@plabottles.eu

- in need of compostable packaging?

- Let's connect

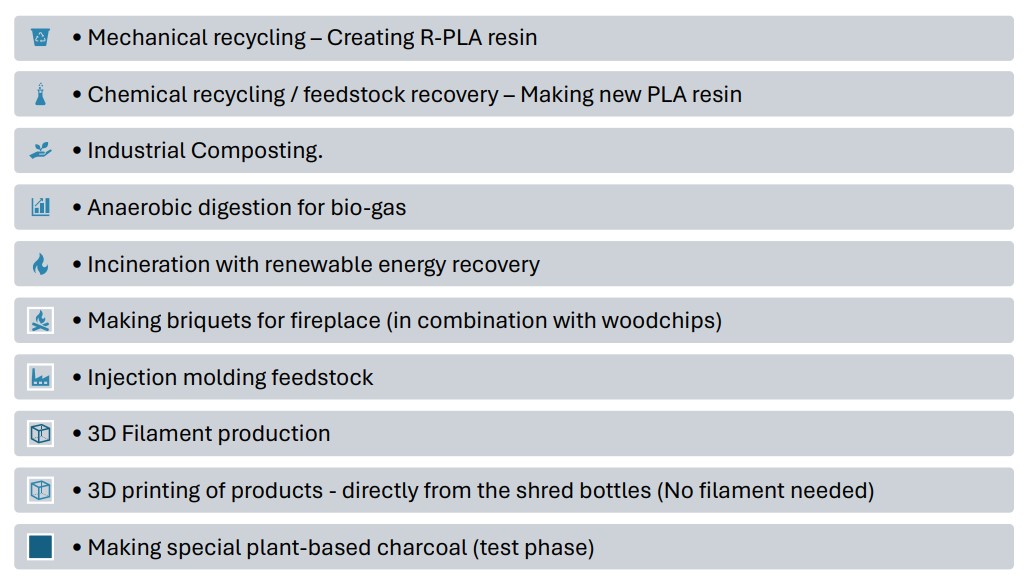

End of life solutions

We distribute our biodegradable water bottles only within “closed-loop” venues, whereby used containers are collected on-site and undergo proper end-of-life processing. Our goal is to get 90% of the PLA bottles back after use, 90% of the time. Collecting the bottles and send them to the right end of life option.

End of life solutions for our biodegradable water bottles

Mechanical Recycling Process: Benefits of Mechanical Recycling:

- Resource Conservation: Mechanical recycling conserves resources by diverting used biodegradable water bottles from landfills and converting them into valuable raw material for new products.

- Energy Efficiency: Compared to the production of virgin PLA resin, mechanical recycling consumes less energy, contributing to overall energy savings and reduced environmental impact.

- Waste Reduction: By recycling PLA bottles through mechanical means, the volume of waste sent to landfills is minimized, promoting waste reduction and environmental sustainability.

- Circular Economy: Mechanical recycling supports the principles of a circular economy by closing the loop on PLA waste and reintroducing recycled material into the production cycle.

Chemical Recycling Process: Benefits of Chemical Recycling:

- Closed-Loop Recycling: Chemical recycling enables a closed-loop system where used PLA bottles are transformed back into high-quality resin, reducing the need for virgin materials and minimizing waste.

- Resource Conservation: By reusing the polymer constituents of PLA, chemical recycling conserves resources and reduces the environmental impact associated with the production of new plastics.

- Energy Efficiency: Chemical recycling typically consumes less energy compared to traditional mechanical recycling processes, making it a more energy-efficient option for managing end-of-life plastics.

- Reduced Landfill Burden: Proper disposal of PLA bottles through chemical recycling reduces the volume of waste sent to landfills, contributing to waste reduction and mitigating environmental pollution.

Industrial composting

Our biodegradable water bottles can also be easily composted in industrial composter facilities.

“compostable” means; material that is certified according to European standards EN 13432 (packaging) and EN 14995 (products) and is composted in industrial composting installations. This process is not about composting at home.

Composting is a biological decomposition process under aerobic conditions over a period of several weeks. The composting of packaging and products takes place in industrial composting installations, under controlled conditions (including temperature, humidity, aeration, and the presence of micro-organisms).

Our biodegradable water bottles can also be composted in these facilities. The compostable bottles can be processed in the same time frame as normal food waste. The end product is CO2, water, and fiber.

Even though it is possible to process our compostable bottles at an industrial composter, it does not mean that this is permitted in all countries. There are several countries in the world where compostable packaging is generally not allowed in Industrial composting facilities. Composting companies have unfortunately made their own rules to keep out bioplastic.

Check carefully in advance whether this end-of-life solution is possible for you. If this is not possible, we will be happy to discuss with you what other options there are.

One of the alternatives to can be anaerobic digestion (makes methane gas which can create energy as a by-product).

End-of-Life 3D Filament Manufacturing from PLA Biodegradable Water Bottles

- Environmental Sustainability: By recycling PLA bottles into 3D filament, we contribute to the reduction of plastic waste and the conservation of natural resources. This sustainable approach aligns with the growing demand for eco-friendly materials in the manufacturing industry.

- Versatility and Performance: R-PLA filament retains the inherent properties of PLA, including biodegradability, low toxicity, and ease of printing. It offers versatility in a wide range of 3D printing applications, from prototyping and product development to artistic creations and educational projects.

- Cost-Effectiveness: Utilizing recycled biodegradable water bottles to produce filament can result in cost savings compared to the production of virgin PLA resin. This cost-effectiveness makes R-PLA filament an attractive option for budget-conscious consumers without compromising on quality or performance.

- Market Differentiation: Offering R-PLA filament demonstrates a commitment to sustainability and innovation, setting our products apart in a competitive market. Consumers increasingly prioritize environmentally responsible choices, making R-PLA filament an appealing option for eco-conscious users.

Anaerobic digestion to create Biogas

Anaerobic digestion is an effective end-of-life solution for managing biodegradable water bottles made from polylactic acid (PLA), particularly when combined with food waste. This process involves the decomposition of organic materials in the absence of oxygen, resulting in the production of biogas as an end product. When PLA bottles are introduced into anaerobic digesters alongside food waste, they undergo microbial breakdown, releasing methane and carbon dioxide gases. These gases can be captured and utilized as biogas, a renewable energy source with various applications.

Combining PLA bottles with food waste in anaerobic digestion systems enhances the efficiency and sustainability of the process. PLA bottles provide additional organic material for digestion, increasing biogas production and overall energy yield. Moreover, PLA’s biodegradability ensures that it can be easily broken down by the microbial activity within the digester, minimizing the need for separate disposal methods.

The end product of anaerobic digestion, biogas, has several valuable uses. It can be used as a renewable fuel for heating, electricity generation, or even as a vehicle fuel. Additionally, the nutrient-rich digestate remaining after digestion can be utilized as a fertilizer, closing the loop on organic waste management and promoting soil health.

Implementing anaerobic digestion for PLA bottles in combination with food waste represents a holistic approach to waste management and renewable energy production. By harnessing the energy potential of organic materials that would otherwise be discarded, this process contributes to greenhouse gas mitigation and the transition to a more sustainable energy system.

Furthermore, anaerobic digestion helps to alleviate pressure on landfills by diverting organic waste from disposal sites. Instead of contributing to methane emissions in landfills, organic materials are utilized to generate renewable energy, reducing environmental pollution and promoting a circular economy.

End-of-Life incineration for energy

When PLA bottles are incinerated for energy recovery, they undergo combustion at high temperatures in specially designed incinerators. The heat generated during combustion is used to produce steam, which can be converted into electricity or utilized for heating purposes. This process effectively harnesses the energy content of PLA bottles, contributing to renewable energy production and reducing reliance on fossil fuels.

One of the key advantages of incineration for PLA bottles is its ability to safely manage organic waste without producing harmful by-products. Unlike traditional plastic incineration, which can release toxic gases and pollutants, the combustion of PLA produces minimal emissions due to its biodegradable nature. PLA is composed of carbon, hydrogen, and oxygen, which are converted into carbon dioxide and water vapor during combustion, resulting in a clean and non-toxic burn.

Furthermore, the ash residue left behind after incineration contains valuable minerals and nutrients, making it suitable for use as a soil amendment or construction material. This closed-loop approach to waste management ensures that even the by-products of incineration can be repurposed in beneficial ways, further enhancing the sustainability of the process.

Overall, incineration offers a safe and efficient end-of-life solution for PLA bottles, enabling the recovery of energy while minimizing environmental impact. When conducted in modern, well-regulated facilities, incineration ensures that PLA waste is managed responsibly, contributing to renewable energy generation and resource conservation.

Our core belief is that PLA bioplastics can have a real and meaningful impact towards creating a better planet for current and future generations. The biobased nature of PLA means that it helps to reduce our carbon footprint.

We believe that in the circular economy, so-called ‘waste streams’ and products at their ‘end-of-life’ can form the basis for new products, instead of being disposed of.