Biodegradable vs. Compostable

Biodegradable vs. Compostable Biodegradable and compostable are two terms that are often used interchangeably, but they actually have different meanings and implications. Understanding the differences

Changing petroleum-based bottles into plant-based bottles.

We represent a manufacturer of PLA bottles – preforms. Compostable, recyclable, burnable bottles for water, milk, and juices. We believe in leaving future generations a healthier planet where consumer product packaging has a lower environmental impact, generates less waste, and is recyclable, compostable, and sustainable.

In 2004, the USA company started with the first-ever PLA milk bottle. In 2008, they switched to solving the problem of one of the most pollutant products in the world—— the petroleum plastic water bottle. The PLA juice bottles and PLA milk bottles are the next logical products that will reduce the single-use plastic waste issues. Some of our plant-based preforms are still in development. If you have questions and would like to know more about the work that is underway, contact us with the button below.

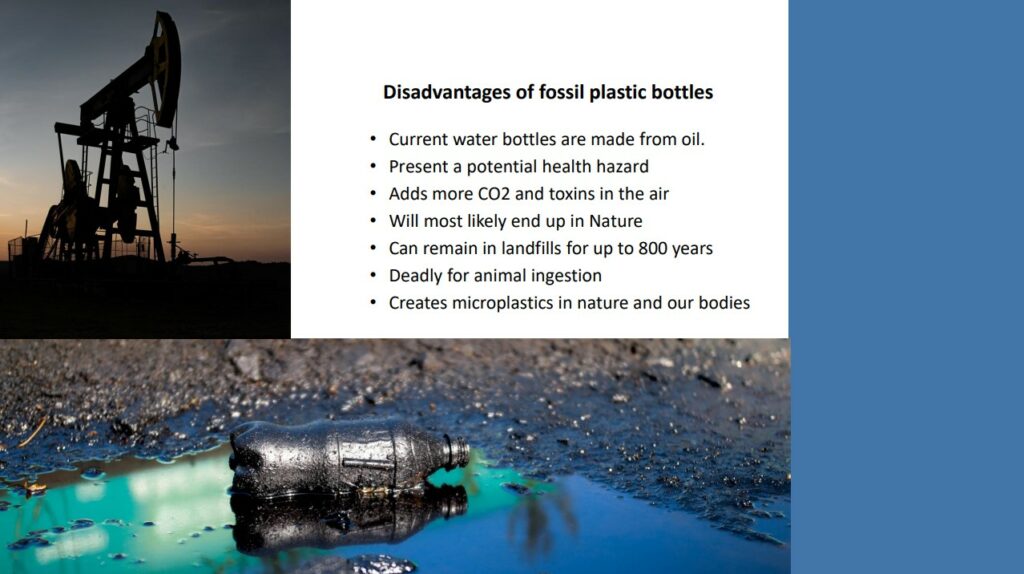

Using a new technique, scientists have been able to identify extremely minute plastic fragments in bottled water, 10 times more than previously counted.

In recent years, there has been rising concern that tiny particles known as microplastics are showing up basically everywhere on Earth, from polar ice to soil, drinking water and food. Formed when plastics break down into progressively smaller bits, these particles are being consumed by humans and other creatures, with unknown potential health and ecosystem effects. One big focus of research: bottled water, which has been shown to contain tens of thousands of identifiable fragments in each container.

One common one was polyethylene terephthalate or PET. This was not surprising, since that is what many water bottles are made of. (It is also used for bottled sodas, sports drinks and products such as ketchup and mayonnaise.) It probably gets into the water as bits slough off when the bottle is squeezed or gets exposed to heat. One recent study suggests that many particles enter the water when you repeatedly open or close the cap, and tiny bits abrade.

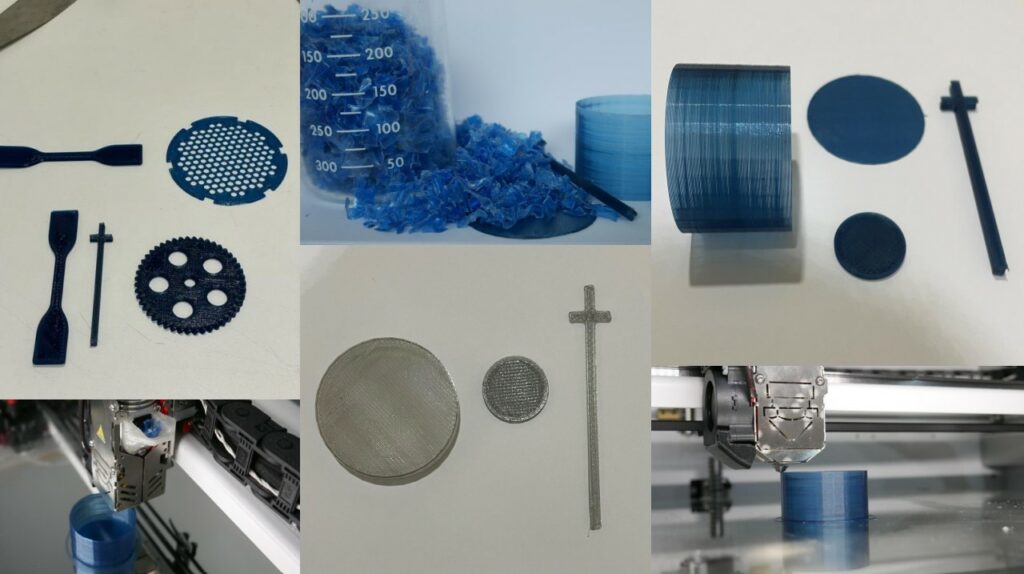

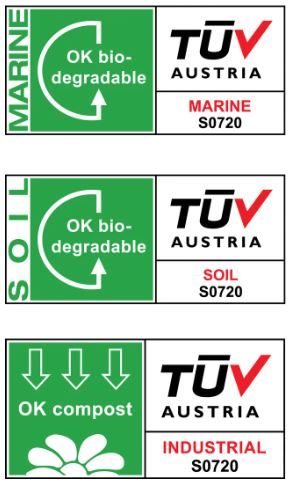

Say goodbye to single-use plastics that harm our planet! At PLA bottles EU, we’re committed to reducing our environmental footprint by replacing petroleum-based items like bottles, straws, and food utensils with eco-friendly alternatives. Our compostable preforms are made with non-GMO, plant-based resins like PLA and PHA, making them a sustainable choice.

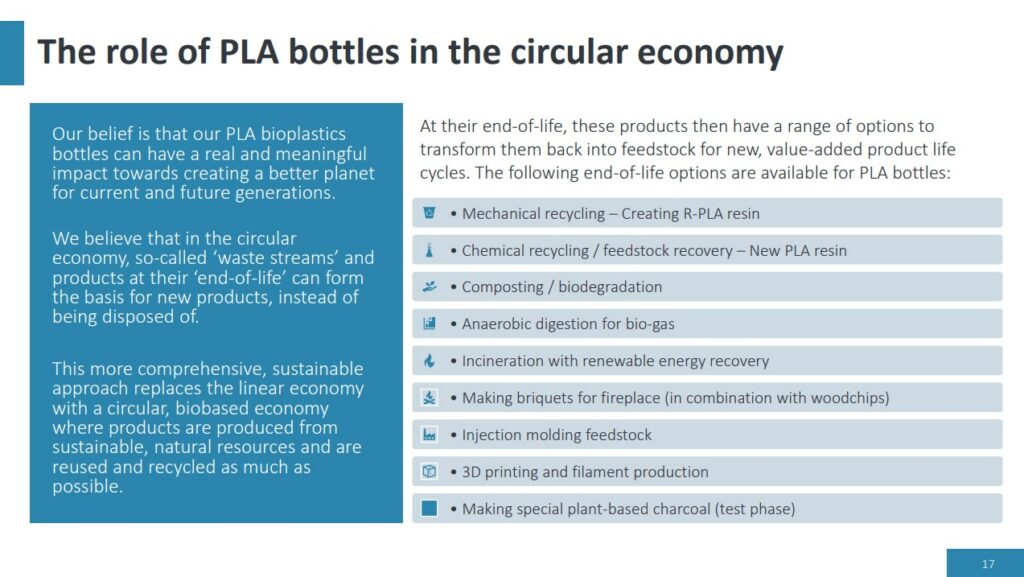

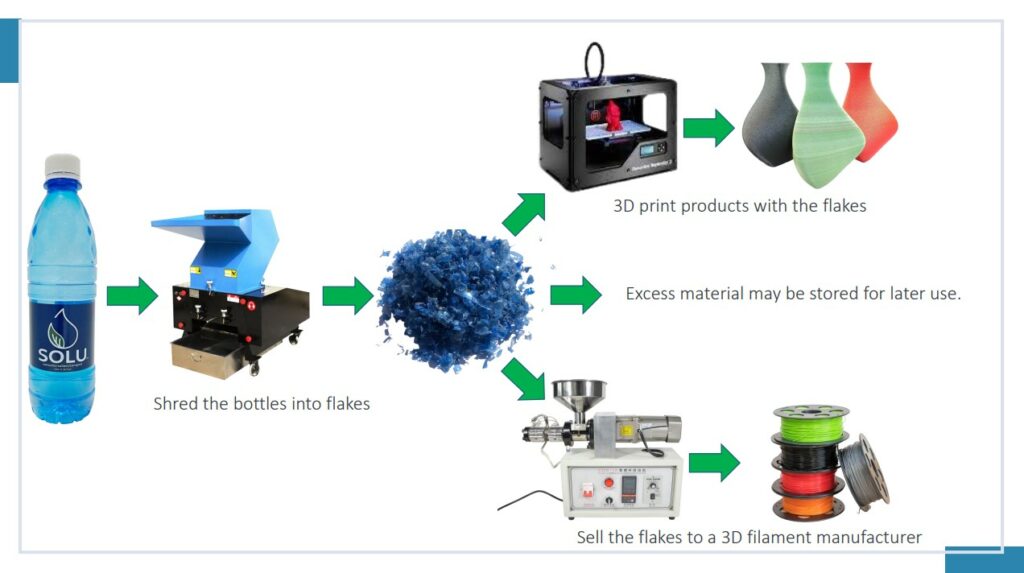

Our PLA bottles can be disposed of in a variety of ways, including industrial composting, recycling, incineration, or even digestion with food waste. We’re also working to create closed-loop systems where empty bottles and caps can be collected and processed properly, reducing truck movements and waste disposal costs.

Together with bottlers, we’re putting our bottles on the market filled with premium water, offering consumers the best water in the world, in the best bottle for the planet. By choosing PLA over fossil plastics, we’re lowering our carbon footprint, creating a circular environment, and helping to create single-use plastic-free locations. Join us in making a positive impact on the world!

PLA bottles of water

Are you interested in PLA bottles filled with water? We now can provide you with a ready-made product, a plant-based bottle of water. We have bottlers in the USA – Canada – Europe – the Gulf area – and South America that can provide you with this high-end product. Our bottles of water are available in 500ml and the blown bottle, label, and cap are made from plants. No toxic fossil plastic is used in this product. A product made with natural raw materials like sugarcane is according to us the best packaging for water.

Contact us for the solutions we have in your area.

Do you want to lower your CO2 emission?

Have less single-use fossil plastic waste?

Have a great marketing tool and create a circular environment?

You are at the right place—at the right time. We would love to work with you to make the Earth a better place to live.

We choose our sites very carefully.

We want to ensure that our PLA bottles are processed in the correct end-of-life solution. This way, we/you create the highest environmental impact with our PLA bottles. That is why we have chosen to only use our plant-based bottles of water in closed-loop locations. This ensures that there is a controlled way to arrange the end-of-life waste stream.

Our goal is to collect 90% of our bottles 90% of the time in order to process them with an “added value” end-of-life solution.

Our PLA bottles have multiple end-of-life solutions, and together with our clients, we look for the best one for their situation. We can use recycling, industrial composting, anaerobic digestion, incineration and digesting machines as a solution.

Many locations are “closed-loop” by definition. Airports, airlines, cruise lines, corporate dining areas, catering companies, sports events, music events, island nations, military bases, universities, hotels, resorts, and restaurants.

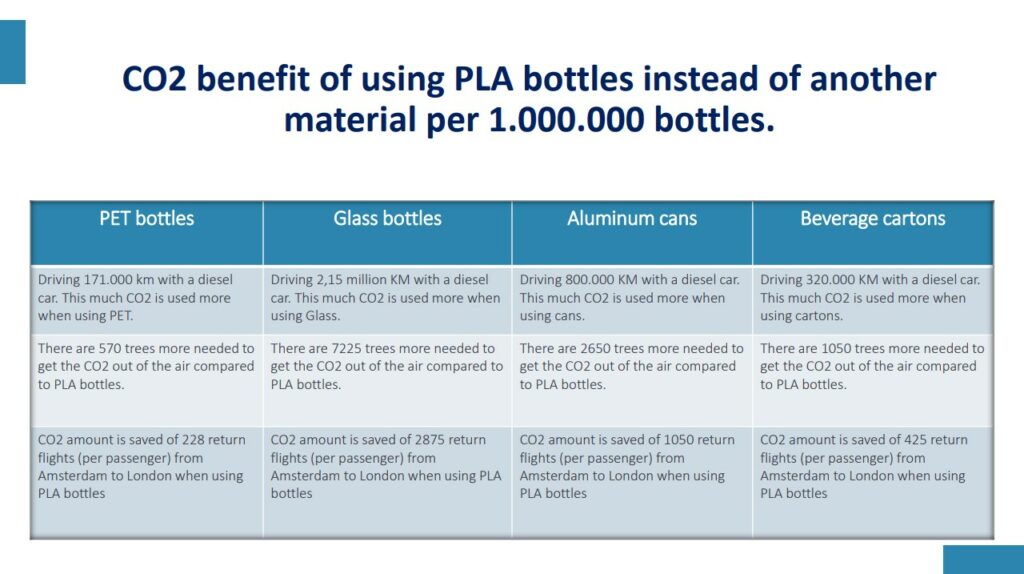

Check out the comparison of the different packaging materials on: CO2 emissions, energy use, and water use.

We are the only company in the world that has a bottle of water on the USDA Bio-preferred list.

Go to the website of USDA

Managed by the U.S. Department of Agriculture (USDA), the goal of the BioPreferred Program is to increase the purchase and use of biobased products.

With our head-office in the USA, an office in the Netherlands and several representatives in key locations of the world, we have a wide network of specialists that can support your plant-based packaging questions.

We believe in leaving future generations a healthier planet. It is time for consumer product packaging to have a softer environmental impact, generating less waste, and is both compostable and sustainable.

Consumer education regarding composting and the use of other more environmentally-friendly waste management actions accompany the distribution of the product line that we represent.

We distribute our plant-based bottles of water only within “closed-loop” venues. Whereby used containers are collected on-site and undergo proper end-of-life processing. Our goal is to get 90% of the PLA bottles back after use, 90% of the time. Collecting the bottles and converting them to an acceptable and even “value-added” end of life option, is a part of our mission.

In 2004, we started with the first in the world PLA milk bottle. In 2008, we switched to solving the problem of one of the most polluting single-use fossil plastic products of the world. “The plastic water bottle.” The PLA juice bottle will become the newest member of our product line. Our R&D team is continuously working on more solutions to the single-use plastic problems around the world. We believe that PHA will have a major role to play in that effort.

Biodegradable vs. Compostable Biodegradable and compostable are two terms that are often used interchangeably, but they actually have different meanings and implications. Understanding the differences

Polylactic Acid (PLA) is a biodegradable, bio-based polymer made from fermented plant sugars. The use of PLA as a feedstock for anaerobic digestion to produce

Article about study: “Assessment of polylactic acid as a feed ingredient for dairy cattle.” – This study, published in the journal “Animal Feed Science and

Compostability Certifications in Australia: An Overview Composting is an important part of waste management and sustainability in Australia, and compostability certifications play a crucial role

Compostability Certifications in the USA: An Overview Composting is an important part of the circular economy and a sustainable way to manage organic waste in

Compostability Certifications in Europe: An Overview Composting is a crucial part of the circular economy and a sustainable way to dispose of organic waste. Europe

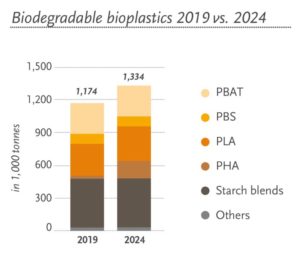

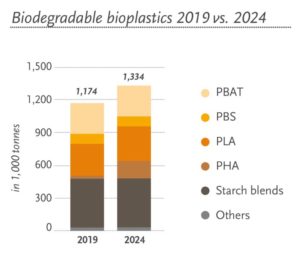

Bioplastics are an essential part of the bioeconomy and a fast-growing, innovative industry that has the potential to decouple economic growth from resource depletion and environmental impact. Bioplastics are a diverse family of materials with differing properties. There are three main groups:

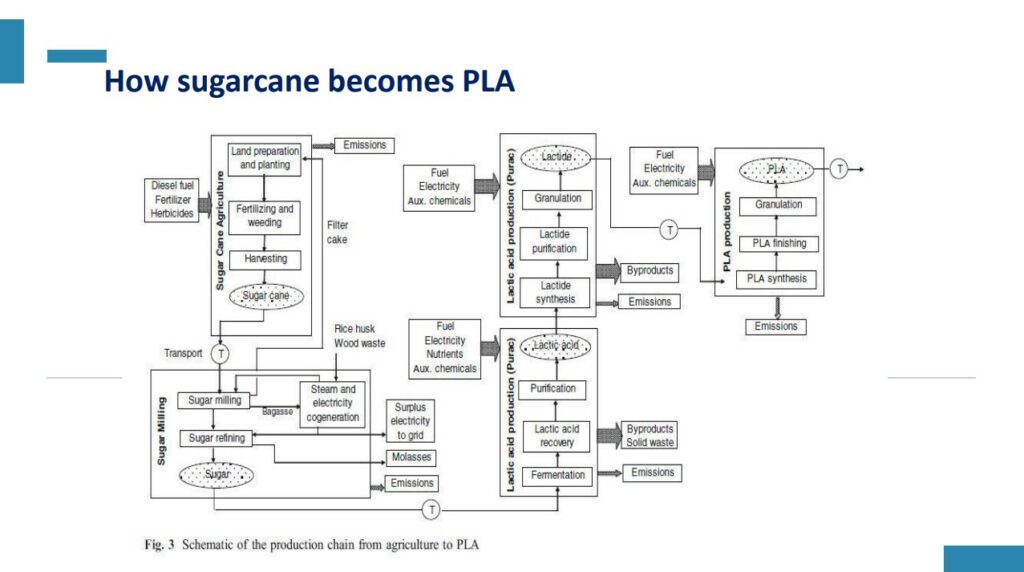

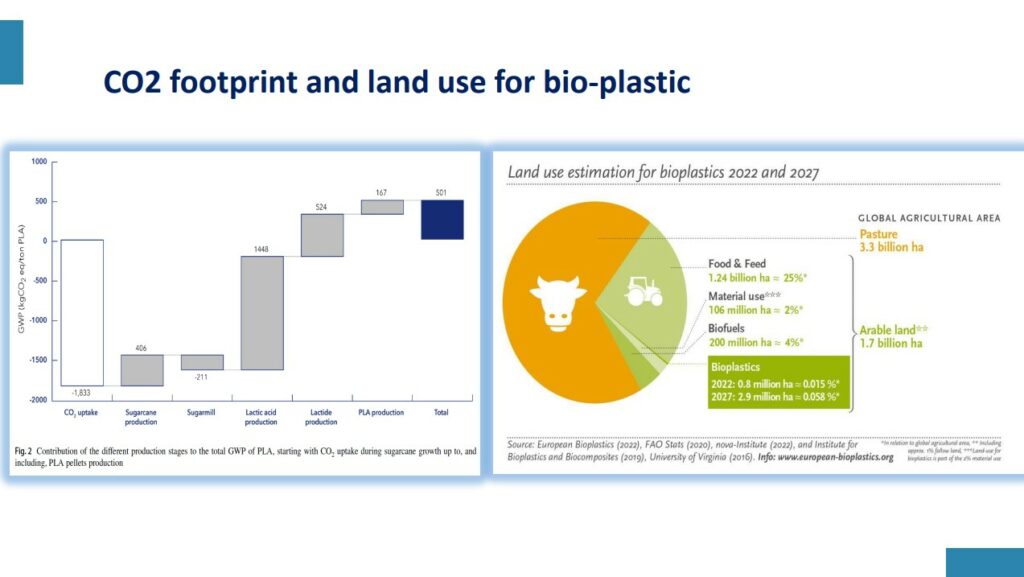

PLA is the bio-plastic that we use for our plant-based bottles, caps, and labels. PLA is one of the bioplastics that has the highest volume of production and is the most widespread bio-plastic in the industry. Our PLA bottles are made from sugarcane and are NON-GMO.

The much newer bio-plastic PHA is at the moment researched and tested within our company to become a candidate for making preforms and bottles.

PLAbottles.eu is part of:

GS-Green packaging

Streetname: De Kreijenbeek 251

Zipcode: 5553BG

City: Valkenswaard

Email: info@plabottles.eu

Phone: +31624845535