- +31-624-845-535

- info@plabottles.eu

- in need of compostable packaging?

- Let's connect

Benefits of PLA compared to other packaging

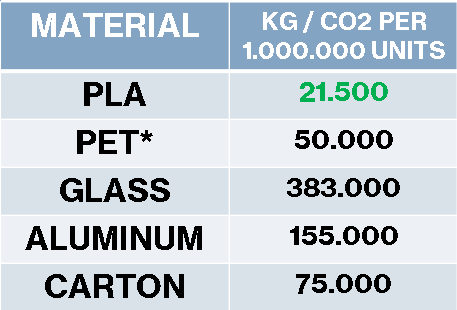

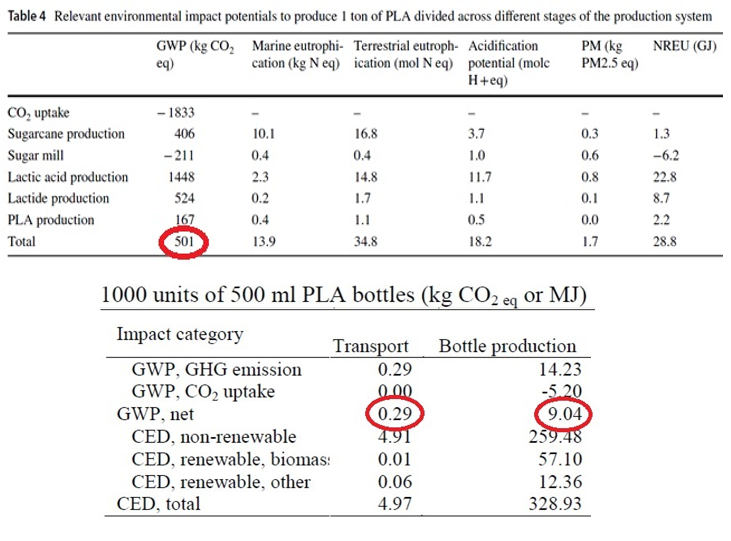

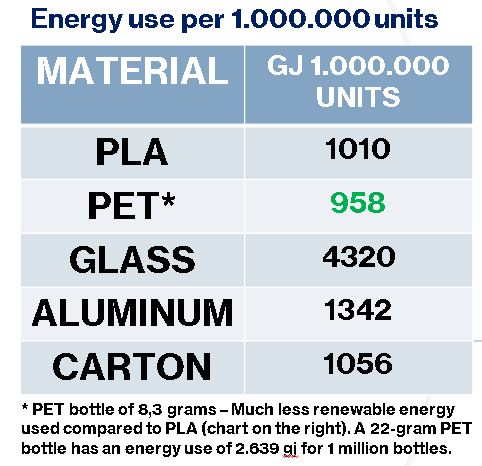

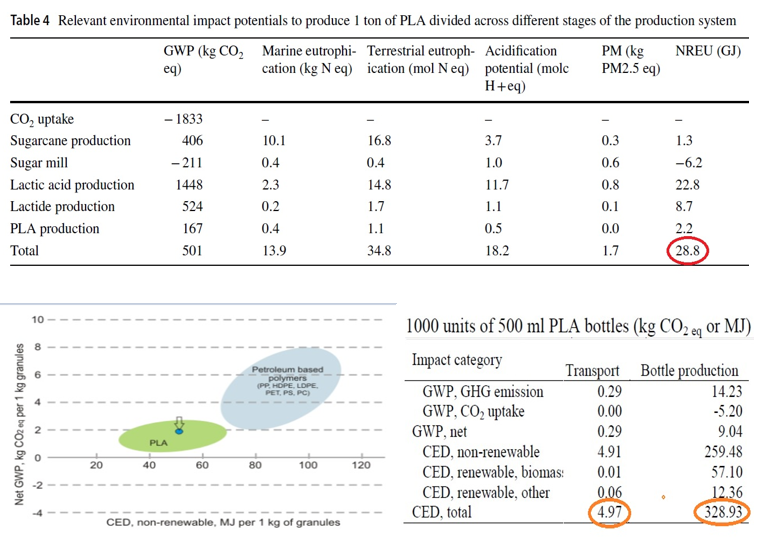

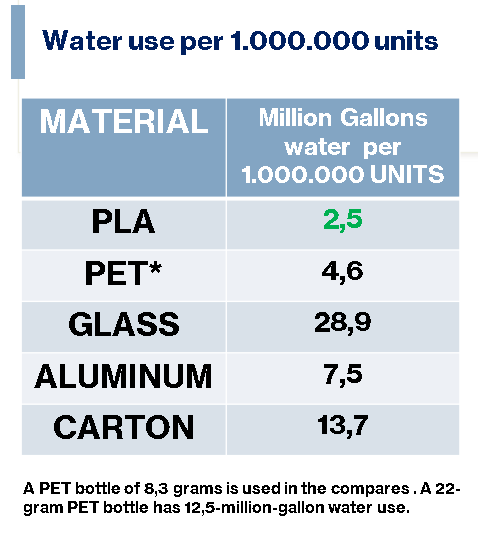

The benefits of PLA compared to other packaging is huge. PLA has multiple end of life options, is made from a renewable resource. Uses much less energy than other packaging and uses more renewable energy during production. Also the CO2 emission in much lower and the water use during production is also lower than every other packaging type. Let us show you some data below.

Benefits of PLA compared to other packaging

The data we uses for showing you the benefits of PLA are all from well known companies and institutes. We have looked at the following liquid packaging types there are.

- PLA bottles

- PET bottles

- Glass bottles

- Aluminum cans

- Beverage cartons

To make the data more clear the comparison of the different packaging materials is per 1.000.000 units. of each packaging type.

Information used for the data shown comes from the following sources:

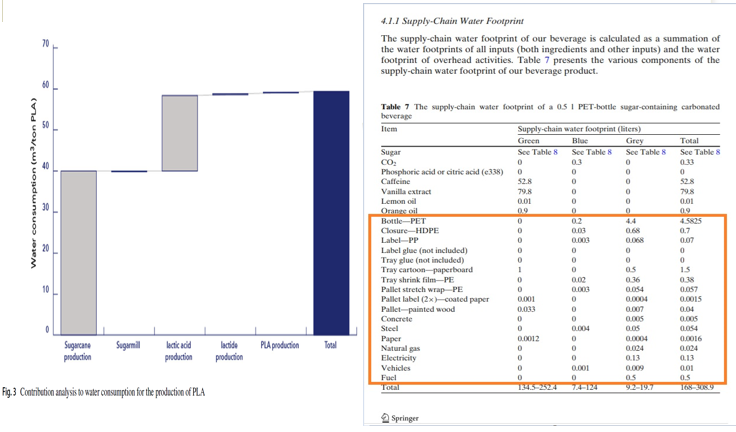

- Corporate Water Footprint Accounting and Impact Assessment: The Case of the Water Footprint of a Sugar-Containing Carbonated Beverage. https://link.springer.com/article/10.1007/s11269-010-9723-8

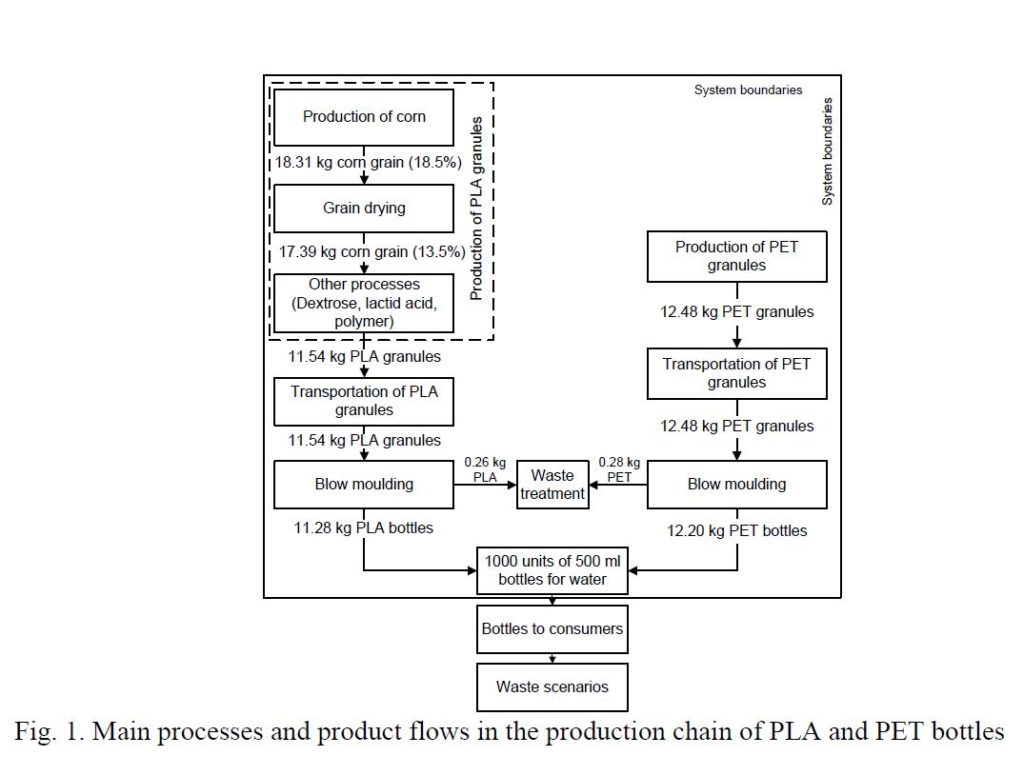

- Corn-based Polylactide vs. PET Bottles – Cradle-to-gate LCA and Implications. https://www.researchgate.net/publication/316418521_Corn-based_Polylactide_vs_PET_Bottles_-_Cradle-to-gate_LCA_and_Implications

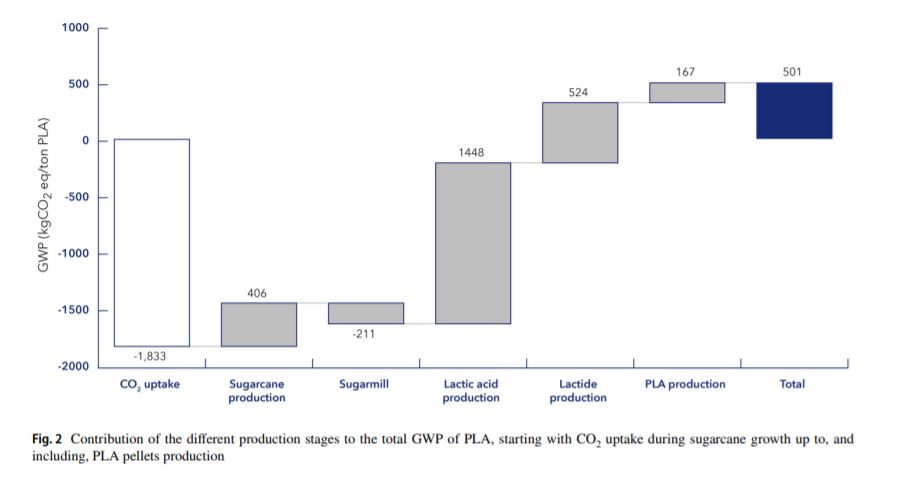

- Life Cycle Impact Assessment of Polylactic Acid (PLA) Produced from Sugarcane in Thailand. https://www.corbion.com/about-corbion/sustainability/life-cycle-assessment

- compares the impact on the environment for the following 16.9 oz packaging options: PET water bottle, aluminum can, beverage carton, and glass bottle. The study also included an assessment of the PET soda bottle. https://bottledwater.org/environmental-footprint/

- Rapport: End-of-life options for bioplastics. Clarifying end-of-life options for bioplastics and the role of PLA in the circular economy.

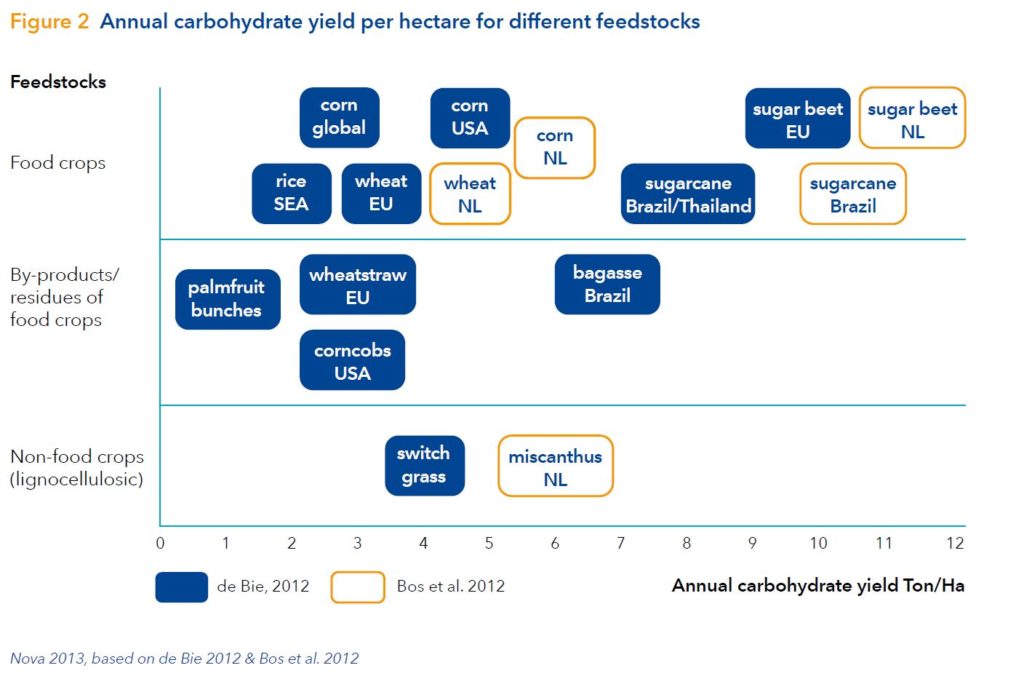

Where our PLA comes from.

Our PLA bottles are made from Sugar cane and produced in Thailand. In the near future, we will also use PLA made from Sugar beet. As you can see on the yield per hectare picture shown above – Sugar cane and sugar beet are 2 of the highest yield per hectare crops used for PLA. Compared to another highly used crop Corn – our PLA needs less plant-based material to generate the same amount of kilo’s PLA.

Weight of our 500ml PLA bottle is 23,5 grams. So when we want to make a 1.000.000 bottles we need 23,5-ton PLA. So in the calculation this number is used to compare with other packaging material to show the benefits of PLA.

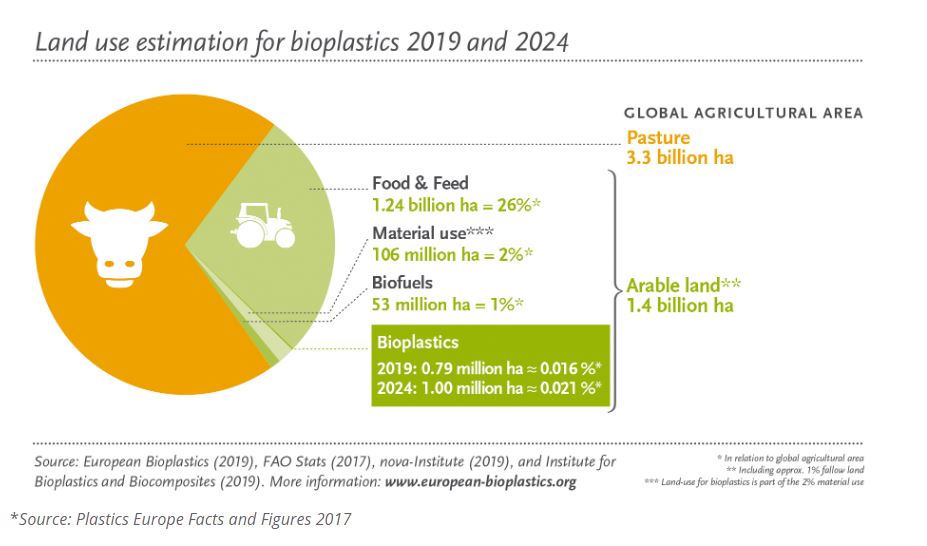

Should we use food crops for bioplastics?

This question is really misleading.

People have been using agricultural raw materials for energy and materials as long as mankind has been on the earth. It is quite common to use agricultural feedstock for biomaterials and this has been done on a large scale for decades. The additional impact of bioplastics is extremely small. The reason for hunger is not a shortage of land for food or animal feed production. We have more than enough space to produce sufficient food to feed everybody. And we are producing the food already. The main reasons for hunger are distribution, logistics and financial resources. Or in other words, mankind is producing enough food and there are still huge areas free or unused. These areas can be used for energy and industrial raw material production without any harm, without any impact on food and animal feed production. Using these areas for energy and industrial materials will provide additional income to many farmers, who will be able to buy food for their families. After all, three out of four poor people in developing countries live in rural areas. Deciding which crops are cultivated for fuel or industrial use on free agricultural areas should only be questions of efficiency, economy, ecology, sustainability etc. – but not a question of whether this crop could be also used as food or animal feed.

CO2 benefits of PLA bottles instead of another material. Per 1.000.000 bottles.

PET bottles

- Driving 171.000 km with a diesel car. This much CO2 is used more when using PET.

- There are 570 trees more needed to get the CO2 out of the air compared to PLA bottles.

- CO2 amount is saved of 228 return flights (per passenger) from Amsterdam to London when using PLA bottles

Glass bottles

- Driving 2,15 million KM with a diesel car. This much CO2 is used more when using Glass.

- There are 7225 trees more needed to get the CO2 out of the air compared to PLA bottles.

- CO2 amount is saved of 2875 return flights (per passenger) from Amsterdam to London when using PLA bottles

Aluminum cans

- Driving 800.000 KM with a diesel car. This much CO2 is used more when using cans.

- There are 2650 trees more needed to get the CO2 out of the air compared to PLA bottles.

- CO2 amount is saved of 1050 return flights (per passenger) from Amsterdam to London when using PLA bottles

Beverage cartons

- Driving 320.000 KM with a diesel car. This much CO2 is used more when using cartons.

- There are 1050 trees more needed to get the CO2 out of the air compared to PLA bottles.

- CO2 amount is saved of 425 return flights (per passenger) from Amsterdam to London when using PLA bottles

Biodegradable - plant-based - PLA - Non-GMO - petroleum free - Safe to burn

Light blue or transparent

Neck size 38mm - in development

Neck size 38mm - in development

100% compostable - plant-based

compost food waste and our bottle

Cups, straws, cutlery, blowmolders etc.

Energy benefits for PLA bottles instead of another material. Per 1.000.000 bottles.

The data the researcher used for PET bottles is based on a 8,3 gram bottle. Most of the single use PET bottles have a much heavier than the 8,3 gram used in this example. A bottle with approximately the same weight as our bottle has a energy use of 2.639GJ per 1 million bottles. More than double than the energy use of a PLA bottle.

Water use per 1.000.000 units benefits

The same PET bottle production, packaging and transportation water footprint for bottles is used in calculating the PLA bottles footprint for this section. (chart below)

1 m3 water = 1000ltr – 1 liter = 0.264172052 US gallon

23,5-ton PLA needed for 1.000.000 bottles

The role of PLA in the circular economy – 6 main areas.

Our belief is that our PLA bioplastics bottles can have a real and meaningful impact towards creating a better planet for current and future generations. We believe that in the circular economy, so-called ‘waste streams’ and products at their ‘end-of-life’ can form the basis for new products, instead of being disposed of. This more comprehensive, sustainable approach replaces the linear economy with a circular, biobased economy where products are produced from sustainable, natural resources and are reused and recycled as much as possible. At their end-of-life, these products then have a range of options to transform them back into feedstock for new, value-added product life cycles. The following end-of-life options are available for PLA:

• Mechanical recycling

• Chemical recycling / feedstock recovery

• Composting / biodegradation

• Anaerobic digestion

• Incineration with renewable energy recovery