- +31-624-845-535

- info@plabottles.eu

- in need of compostable packaging?

- Let's connect

Blogs PLA Bottles.eu

The world of bio-plastics (PLA) is not standing still. Every day, every week, and every month new ideas are developed and new products are created, materials, and methods to make the world more sustainable.

The purpose of the blogs is to familiarize you as a reader with bio-plastics, in particular PLA, and the existing and new applications that exist.

Every day we are busy developing new ways to make our products even better. Together with our partners all over the world, we are making great strides.

There are several other topics that we would like to tell you more about. Some groundbreaking, others more general, but no less important. So keep coming back to the blog page and see what’s new.

Article about study: “Assessment of polylactic acid as a feed ingredient for dairy cattle.” – This study, published in the journal “Animal Feed Science and Technology,”

Polylactic Acid (PLA) is a biodegradable, bio-based polymer made from fermented plant sugars. The use of PLA as a feedstock for anaerobic digestion to produce biogas has gained attention as a way to reduce waste and produce renewable energy.

Biodegradable and compostable are two terms that are often used interchangeably, but they actually have different meanings and implications.

This study aims to calculate the water and land footprint of bioplastics in several scenarios where all plastics are bio-based and assume different types of biomaterials and recycling rates.

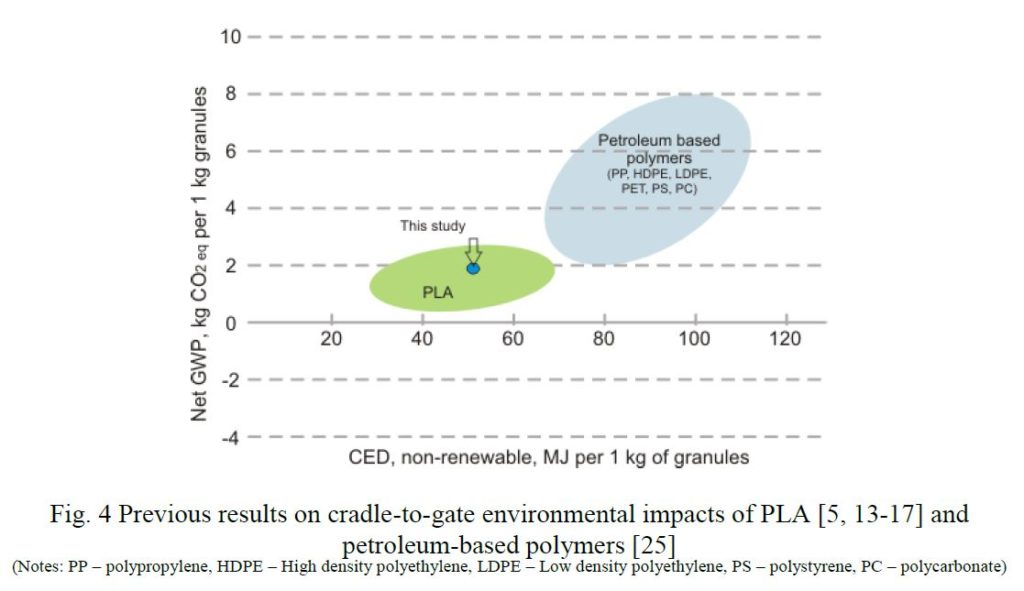

The aim of this paper is to analyse the performance of PLA bottles compared to other alternatives currently in use in the milk packaging sector, using the life cycle assessment (LCA) methodology.

In this debate it is brought forward that it is still unclear whether the disintegration rate of compostable products would be sufficient to be compatible with the current GFT treatment practice in the Netherlands.

The US has established compostability certifications. In this article, we’ll look at the different compostability certifications in the United States.

Composting is an important part of waste management and sustainability in Australia, and compostability certifications play a crucial role in ensuring that organic waste is disposed of in an environmentally friendly manner.

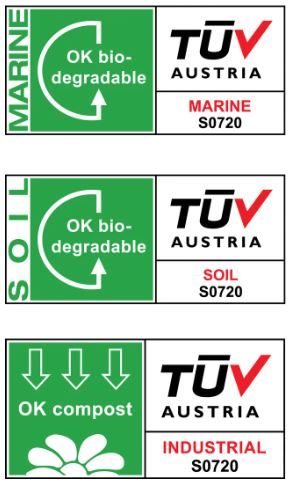

In this article, we’ll look at the different compostability certifications in Europe, focusing on the differences between industrial compostable, home compostable, and marine compostable certificates.

Dutch tv program about compostable packaging. (Dutch with English subtitle)

We make bottles differently. We use plant-based material. Not the toxic fossil plastic made from oil, sugarcane is our resource.

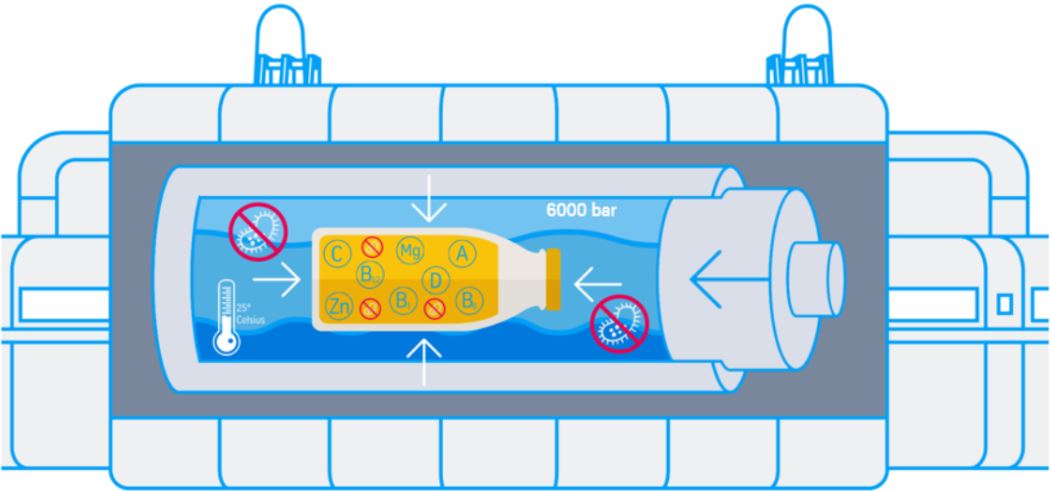

The aim of the present PET – PLA bottle HPP treatment study is to assess the use of polylactic acid (PLA) bottles as an alternative to PET ones for high-pressure processing (HPP) of apple juice.

PLA and the circular economy, so-called “waste streams” and products at the end of their useful life form the basis for new ones products, instead of being thrown away.

Bioplastics fit well in a circular economy, especially if they are recycled as much as possible at the end of their lifespan (CE Delft, 2017a). Some bioplastics, such as bio-PET and bio-PE, are already partially recycled.

The study compares the environmental impacts of 500 ml water bottles produced from corn-based polylactide – Poly lactic acid (plant-based bottles) and PET.

Several results are interesting: the PLA yield (share of PLA, which is sorted out correctly), the purity of the PLA stream (share of PLA in the PLA stream) and the pollution of PLA in the PET stream (share of PLA in the PET stream).

The aim of this work is twofold: first, to analyse what might be the best end-of-life (EOL) option for PLA food packaging with food content and second, to determine which life cycle stage has the biggest impact.

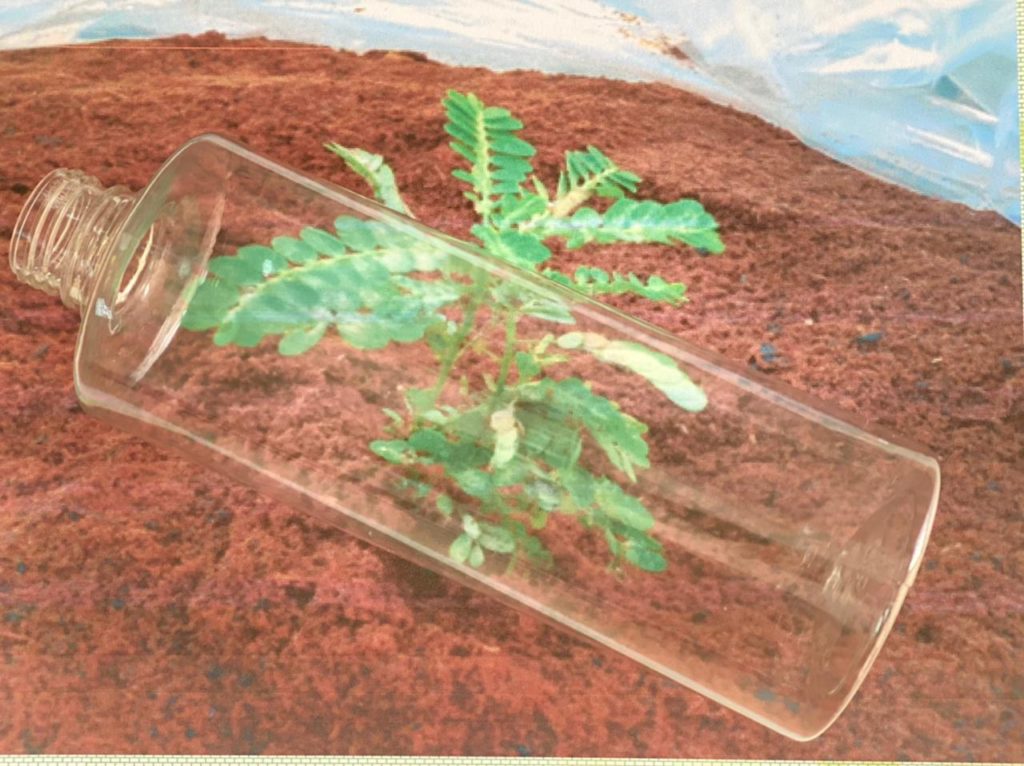

Biodegradable water bottles from PLAbottles.eu are, as far as we know, the only bottles that are completely 100% plant-based. We have a bottle, CAP, and label that is made from 100% plant-based material.

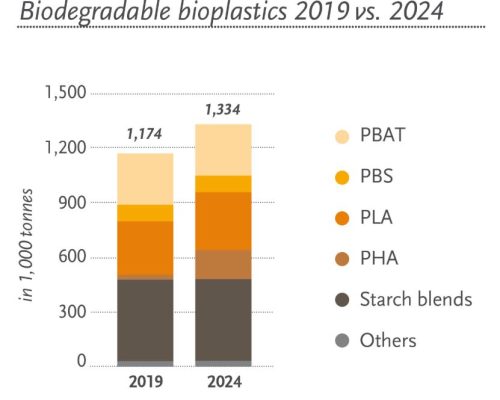

The term “bioplastic” refers to a plastic substance that is (wholly or partly) based on organic biomass instead of petroleum. Many bioplastics are biodegradable, which – in theory – is one of their biggest advantages

ASTM D6400 is the standard specification for solid material biodegradation (by composting) required for the labeling of plastics designed to be aerobically composted in municipal or industrial facilities.