- +31-624-845-535

- info@plabottles.eu

- in need of compostable packaging?

- Let's connect

Compostable water bottles

Since 2008 we produce PLA preforms for compostable water bottles. Starting with our “green bottles” and now the light blue and clear preforms, along with dark green and white closures, all are 100% plant-based and 100% non-gmo.

More information

Compostable water bottles, how did it start?

Our journey in crafting PLA preforms for compostable water bottles began in 2008. Our compostable water bottles earned distinction as a part of the “Green the Capital Initiative,” an initiative championed by then Speaker Nancy Pelosi at the House of Representatives. A commendable instance of a “closed-loop” program emerged as various US government buildings engaged in recycling the bottles, transporting them to the USDA’s Beltsville, MD Compost Facility situated in Maryland. However, during that period, the development of a compostable cap remained an unattained goal for manufacturers of PLA bottles.

In more recent times, the summer of 2018 witnessed a significant outdoor event in New York City embracing the use of our compostable water bottles, complete with compostable caps. The practice extended to various major events as well. A critical requirement for a seamless waste processing trajectory is that the bottle, cap, and label must all be composed of plant-based plastic. This ensures that the materials can be effectively managed across diverse “end of life” scenarios. The inclusion of a petroleum-based plastic cap necessitates two distinct end-of-life streams. While the bottle demonstrates proficient composting properties, the cap and the encircling ring on the bottle’s neck resist decomposition, introducing contaminants to the composting process. In contrast, our bottle combustion yields no harmful emissions; however, this claim doesn’t extend to the plastic cap. Moreover, in the realm of recycling, the presence of petroleum-derived components like the tamper-evident band can lead to contamination, undermining the integrity of the PLA.

In light of these considerations, the time had come to undertake the development of a fully plant-based compostable cap. This pursuit spanned nearly five years, characterized by trials and errors, culminating in the creation of a compostable closure. Consequently, our compostable water bottles, alongside their cap and label, have successfully transitioned to a 100% plant-based composition. This product can be seamlessly integrated into recycling processes, composting facilities, boilers, and potentially even subjected to digestion in a specialized digester, a project that has seen ongoing research and development for nearly a decade.

Presently, our PCO1810 preform and closure stands poised for mass production. With a weight of 23.5 grams, this preform, featuring a 28mm neck is ideally suited for 350ml up to 500 ml bottles.

Compostable water bottles - now and the future

In 2023/24, we will also start producing additional preforms to meet other bottling needs. The speed of that development will depend on the demand from the market and the bottlers who choose to join us. Of course, in addition to the different neck shapes, we will also produce different sizes preforms. This allows compostable water bottles from 0.33ml to 1.5 liters or larger to be blown with our plant-based preform.

We want to ensure that our bottles are always placed in venues where the correct end of life solution can occur. That is why we have chosen to only use our plant-based bottles in closed-loop locations. Our goal is to collect 90% of our bottles 90% of the time in order to process them properly.

We see that in normal retail it is difficult to create a good end of life for plant-based bottles. In normal retail, PET bottles are usually recycled separately or sorted out among the household waste. A PLA recycle flow in normal household waste has not yet been developed in most countries of the world, because the amount of PLA waste is still too small to be a factor to be dealt with. Within industrial composting, there is still a lot of uncertainty because there have been almost no bottles that have carried a compostable closure—until now. There is a lot of miscommunication about how to deal with plant-based packaging in the waste stream and some people think that every plant-based packaging simply composts in the wild. This is incorrect, there are different plant-based packaging and they do not compost the same. There are those that can compost in the wild and in water and some only compost in special circumstances such as in an industrial composting facilities. In the case of our compostable water bottles, they compost in an industrial composting facility and multiple other options as well.

Because of all these points above, we, therefore, choose not to sell our biodegradable bottles with water in normal retail, but only in closed-loop venues. If you are interested in switching with your company or brand to a more sustainable bottle for water, please contact us. We are happy to look at the possibilities of how we can use our water bottles in a closed loop to make your company come into the 21st century of environmental awareness.

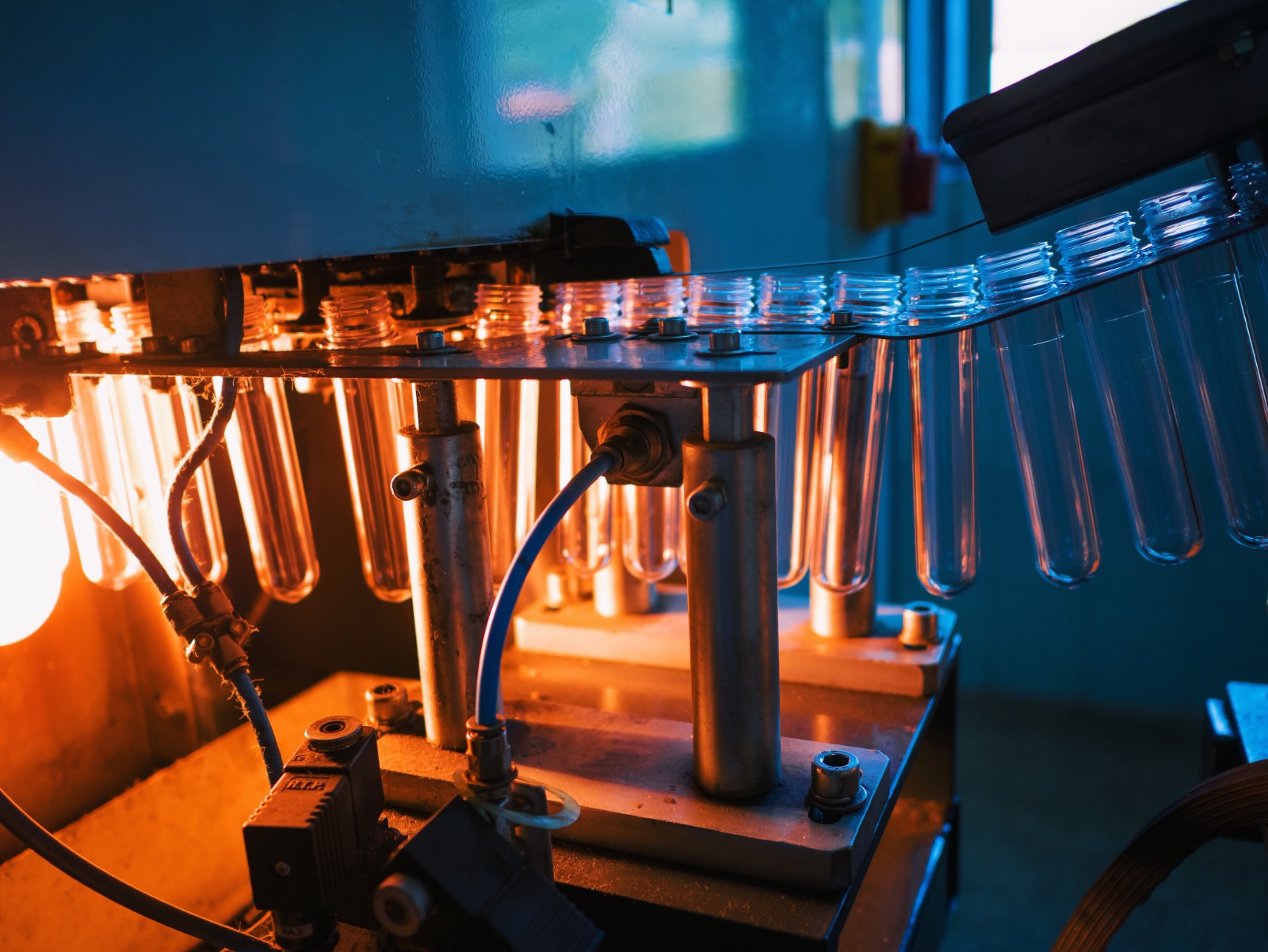

The new factory for mass producing PLA bottles and caps

Play Video about biodegradable preforms

Our compostable water bottles pilot locations

Coming soon

One of the largest cruise lines is replacing all their fossil plastic water bottles. Using our bottles and our patented “BMD machine”. This will lower their CO2 footprint, creates a circular environment, lowers waste disposal costs and minimize single-use fossil plastic.

Coming soon

An airline with their home-base UAE wants to be fossil plastic-free on all of their flights. They make it happen with our plant-based bottles.

International regulation requires cabin waste to be send to an incinerator. Our bottle is safe to burn with no toxic outcome.

Ideal closed loop location

Previous slide

Next slide

We distribute our plant-based compostable water bottles only within “closed-loop” venues, whereby used containers are collected on-site and undergo proper end-of-life processing. Our goal is to get 90% of the PLA bottles back after use, 90% of the time. Collecting the bottles and send them to the right end of life option. We, therefore, look at closed loop locations for our products.

A lot of locations can be set up as a close loop location. Some are better equipped than others to become a fully closed loop for our bottles. Ideal locations for a closed-loop are catering companies, events, restaurants, cruise lines, hospitals, airports, airlines.

Our PLA bottles have multiple end of life solutions. Every end of life has its own benefits and together with our clients, we decide per location the best end of life solution. We monitor the outcome of the collection and will support getting the highest returns of our plant-based bottles of water.

Does your company need to lower CO2, create a circular environment, lower costs for waste pickup and become single-use plastic free? We supply a full package to create all of this in a closed-loop situation.

With a combination of our unique bio plastic products, other compostable products and our special digester machines we can create this solution for your location. Our digester will compost all bio-plastics and all food waste within 24/48 hours into liquid compost that can be stored and sprayed over the land or transported into the sewage system if needed. This way locations all over the world can be made more environmentally friendly without the need for an external waste facility.

With our solution you can create your own closed-loop location.