Biodegradable vs. Compostable

Biodegradable and compostable are two terms that are often used interchangeably, but they actually have different meanings and implications. Understanding the differences between these two terms is important for making informed decisions about waste management and reducing the impact of human activities on the environment.

Biodegradable

Biodegradable refers to materials that can be broken down into natural elements by microorganisms, such as bacteria and fungi, over a period of time. This process is called biodegradation. The biodegradation of organic matter is a natural process that occurs in the environment, and it helps to recycle nutrients back into the ecosystem.

The time it takes for a material to biodegrade depends on several factors, including the type of material, the environment, and the presence of microorganisms. For example, a piece of fruit will biodegrade much more quickly than a plastic bag. Some biodegradable materials, such as paper, can break down in just a few weeks, while others, such as synthetic materials, can take hundreds of years to biodegrade.

Compostable

Compostable refers to materials that can be broken down into natural elements and used as a nutrient-rich soil amendment, commonly referred to as compost. Composting is a process of controlled biodegradation that can take place in a compost bin, compost pile, or composting facility.

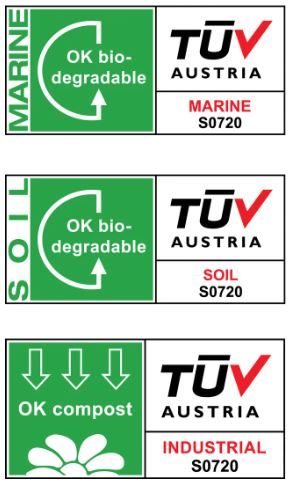

To be considered compostable, a material must meet certain criteria. It must biodegrade into carbon dioxide, water, and organic matter in a short period of time, typically within 90 days. It must also break down into a compost that is safe for plants and the environment, free of harmful chemicals and pathogens.

Compostable materials include food waste, yard waste, and some biodegradable plastics. Compostable plastics are made from renewable resources, such as corn starch or sugarcane, and are designed to break down into compost under specific conditions.

Differences between Biodegradable and Compostable

The main difference between biodegradable and compostable is the end result of the biodegradation process. Biodegradable materials can break down into natural elements over time, but they may not necessarily be transformed into compost. Compostable materials, on the other hand, are designed to break down into compost and contribute to the growth of plants.

Another important difference is the time frame in which biodegradation occurs. Biodegradable materials can take a long time to break down, while compostable materials are designed to biodegrade in a short period of time, typically within 90 days.

The environmental impact of biodegradable and compostable materials also differs. Biodegradable materials can release methane, a potent greenhouse gas, as they break down. Compostable materials, on the other hand, release carbon dioxide, a less potent greenhouse gas, and contribute to the growth of plants.

It’s also important to note that not all biodegradable materials are compostable, and not all compostable materials are biodegradable. For example, some biodegradable plastics can take hundreds of years to biodegrade, while some compostable materials, such as yard waste, are not biodegradable.

Conclusion

Biodegradable and compostable are two terms that are often used interchangeably, but they have distinct meanings and implications for waste management and the environment. Biodegradable refers to materials that can be broken down into natural elements over time, while compostable refers to materials that can be transformed into compost and used to support plant growth.